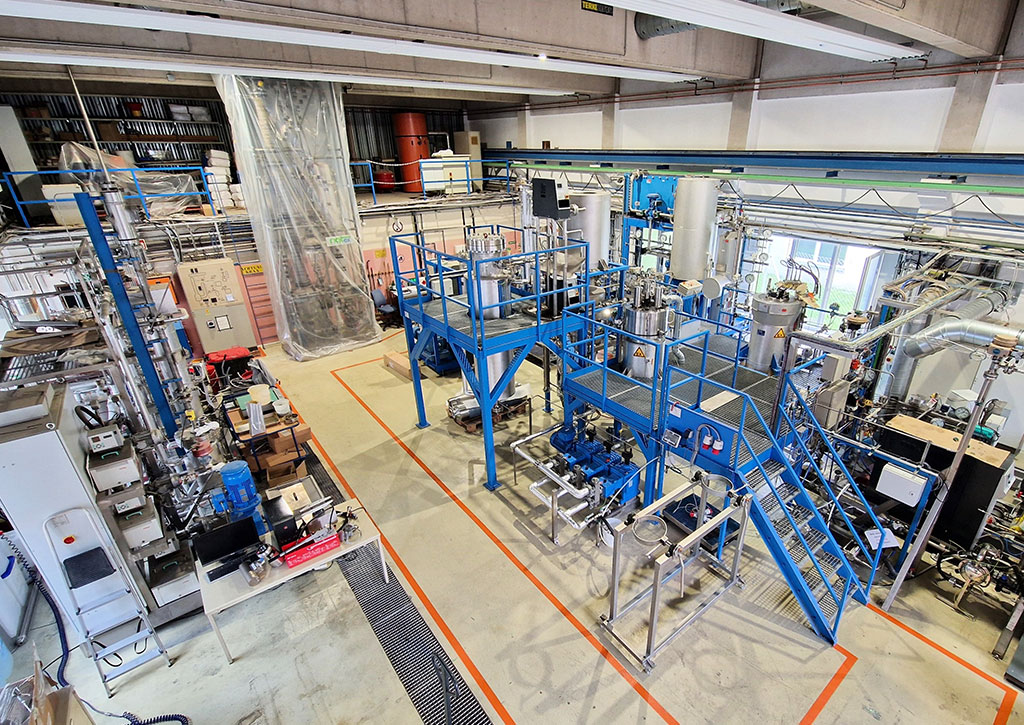

Research and Development Services for Supercritical CO2 Processes

At our technical center, we specialize in developing and optimizing supercritical fluid processes of every type. Whereas the majority is supercritical CO2 extraction of solid raw materials, it can also be impregnation, fractionation, powder generation or even completely new process. Our experts specialize in CO2 as a process fluid and are eager to help you getting the best out of your individual product.

With over 30 years of experience, NATEX has worked on more than 300 different raw materials, in various industries such as food, pharmaceuticals, cosmetics, recycling, chemicals, wood and many more. This extensive experience can speed up the process during the development and especially the know-how around industrialization ensures that the collected data and the developed process can also be scaled up later on.

Our 5L supercritical CO2 extraction unit allows us to fine-tune parameters such as pressure (up to 800 bar), temperature (up to 200°C), solvent-to-feed ratio, CO2 flow rates, and extraction time in a short period of time by screening different conditions. This allows us to get an initial understanding of the material and how it needs to be processed to achieve a quality that is suitable for the client. It can also work with co-solvents like ethanol as an entrainer to increase the polarity of the apolar CO2.

On our 80L Pilot plant we are then able to collect data about the scalability of a process. This includes material handling, channeling, and results in more reliable data for further steps. This machine can work up to 460 bar / 100 °C. It is also equipped with equipment for impregnation and an injection ethanol or other co-solvents is possible. The data it provides is regularly compared to industrial plants and is proven to be an accurate basis for further estimations like CapEx (Capital Expenditure) and OpEx (Operational Expenditure).

Our supercritical CO2 thin film extractor or our packed column can also work with fluids or viscous pastes. While the fractionation column allows to fractionate liquid mixtures, the thin films addresses other pumpable materials and allows to split them into different fractions or to clean them from unwanted substances.

View cells are available up to 400bar und 150°C, also agitated to visually see materials in liquid or supercritical CO2 which is often interesting to better understand its behavior during processing and to explain certain behaviors which are otherwise difficult to understand.

In our “Technikum” we also have a long list of other devices to prepare the materials, refine them or to make basic analysis. This includes: