Food and nutraceuticals

The food and nutraceutical industry of today is searching for natural ingredients that are free from harmful substances. Supercritical-CO2 extraction has been established as a “green” and sustainable technology and represents an attractive alternative to traditional methods. Solvent-free products are key elements of health-promoting functional food and ingredients. This technology allows for the extraction of high-quality compounds without the use of harmful solvents, ensuring that the final products are safe and beneficial for consumers.

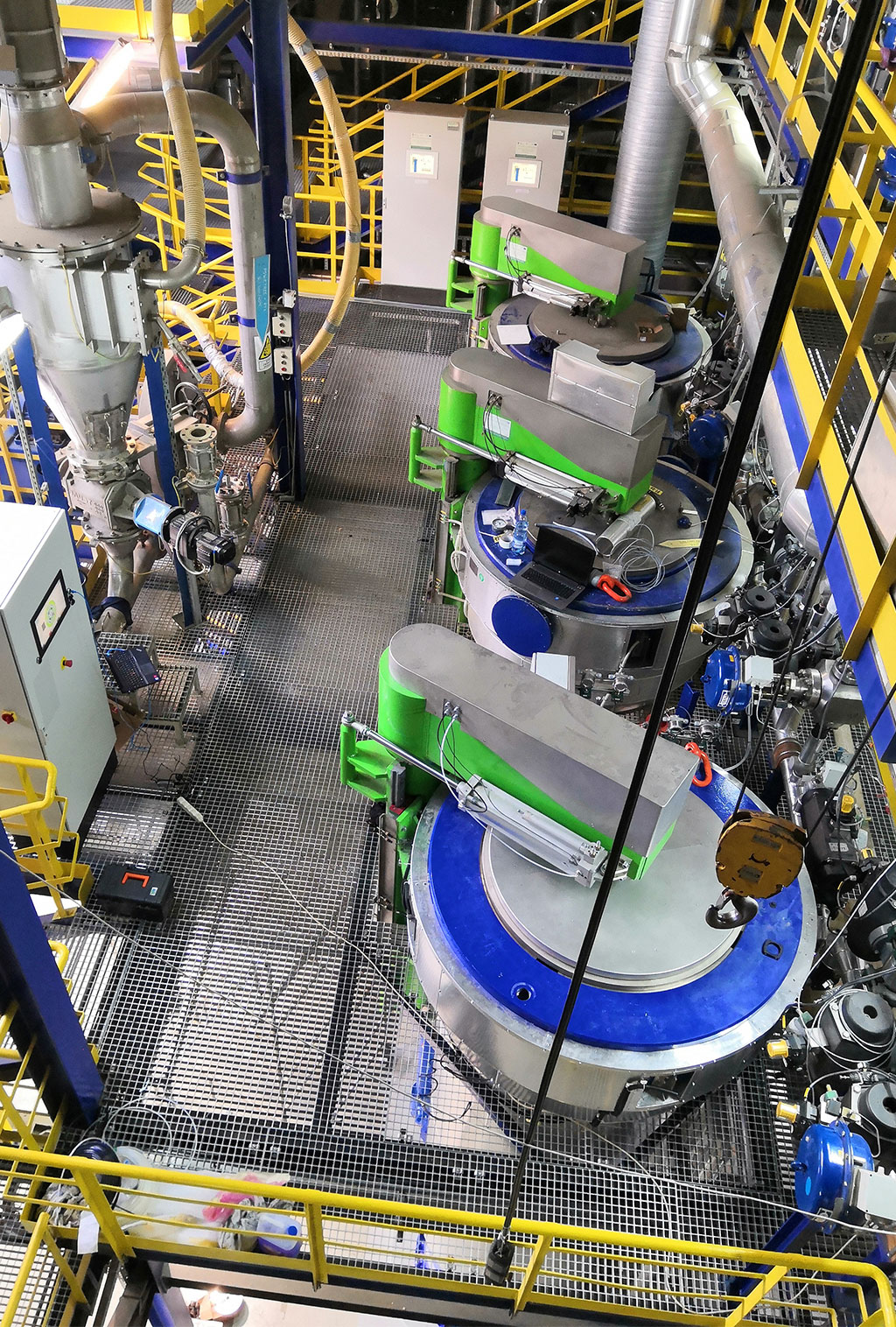

Pioneers in hygienic large-scale solutions

The most challenging requirement for CO2-based processes in the food industry is the large capacity. By building the biggest plants in the world and by continuously challenging the status quo, NATEX ensures the profitability of the processes. Increasing the size of a plant not only makes it more economical but also more sustainable. This is achieved by installing advantageous CO2 recovery systems and energy optimization. Our extraction plants with hygienic design deliver the highest quality of extracts and comply with the current requirements of regulatory bodies.

Large-scale CO2 extraction plants are designed to handle significant volumes of raw materials, making them suitable for industrial applications. These plants are equipped with advanced CO2 recovery systems that minimize the consumption of CO2 and reduce operational costs. Energy optimization techniques are employed to ensure that the processes are efficient and environmentally friendly. By leveraging these technologies, NATEX is able to provide solutions that are both economically viable and sustainable.

Organic certification

Organic certification plays an increasingly important role for the entire food and nutraceutical industry. By using CO2, organic certifications can be easily achieved. Supercritical CO2 extraction is a clean process that does not involve the use of any toxic or synthetic chemicals, making it ideal for producing organic products. The process itself is compliant with organic standards, ensuring that the final products can also be certified as organic.

Organic products are increasingly in demand as consumers become more health-conscious and environmentally aware. The ability to produce organic extracts using supercritical CO2 technology provides a competitive advantage for companies in the food and nutraceutical industry. These products are perceived as healthier and more sustainable, aligning with the preferences of modern consumers.

Applications

Future prospects

The future of supercritical CO2-based processes in the food and nutraceutical industry looks promising. As the demand for natural and organic products continues to grow, the need for clean and sustainable extraction technologies will increase. Ongoing research and development are expected to further enhance the capabilities of supercritical CO2 extraction, making it even more efficient and versatile.

Innovations in equipment design and process optimization will continue to drive the adoption of supercritical CO2 technology in the industry. As companies strive to meet the evolving preferences of consumers, the use of supercritical CO2 extraction will play a crucial role in delivering high-quality, safe, and sustainable products.