Supercritical Impregnation with CO₂: Advancements and Applications

Supercritical carbon dioxide (CO₂) has improved impregnation processes across various industries due to its unique thermophysical properties. Its low viscosity and high diffusivity enable it to penetrate porous materials more effectively than traditional methods. This results in a more uniform and efficient distribution of impregnation agents within the substrate.

One of the key advantages of supercritical CO₂ is its tuneable solvating power, which can be adjusted by modifying pressure and temperature conditions. This allows for precise control over the impregnation process, ensuring optimal interaction between the CO₂, the impregnation agent, and the material.

Applications of Supercritical Impregnation:

The established processes based on this technology include:

Wood Preservation

Superwood A/S in Denmark exemplifies the use of supercritical CO₂ in wood treatment. By impregnating wood with preservatives using CO₂ as the solvent, they achieve an even distribution of protective agents throughout the wood. This enhances durability and resistance to pests and environmental degradation without introducing harmful chemicals. Besides this process allows to treat spruce which is a refractory species to which the normal pressure impregnation processes cannot be applied.

Medical Materials

Supercritical CO₂ is employed to impregnate bandages and medical devices with antibiotics or antimicrobial agents, also implants with beneficial substances that facilitate the healing. This process not only sterilizes the materials but also imbues them with properties that promote healing and prevent infection.

Textile Enhancement

Fabrics are impregnated with dyes, flame retardants, or functional additives using supercritical CO₂. The process ensures deep penetration of these agents without damaging the fabric or leaving residual solvents that could affect skin contact. It also has the potential to avoid hazardous wastewater streams which are full of toxic chemicals.

Pharmaceuticals generation

The technology is used to load active pharmaceutical ingredients into carriers for controlled drug release. This enhances bioavailability and allows for targeted delivery systems in medications.

Electronics and Sensors

Impregnation of polymers and other substrates with conductive materials improves the performance of electronic components and sensors, offering advancements in fields like wearable technology.

The use of supercritical CO₂ in impregnation processes represents a significant advancement towards greener and more efficient industrial practices. Its unique properties not only improve product quality but also align with environmental and safety standards, making it a valuable tool in modern material processing.

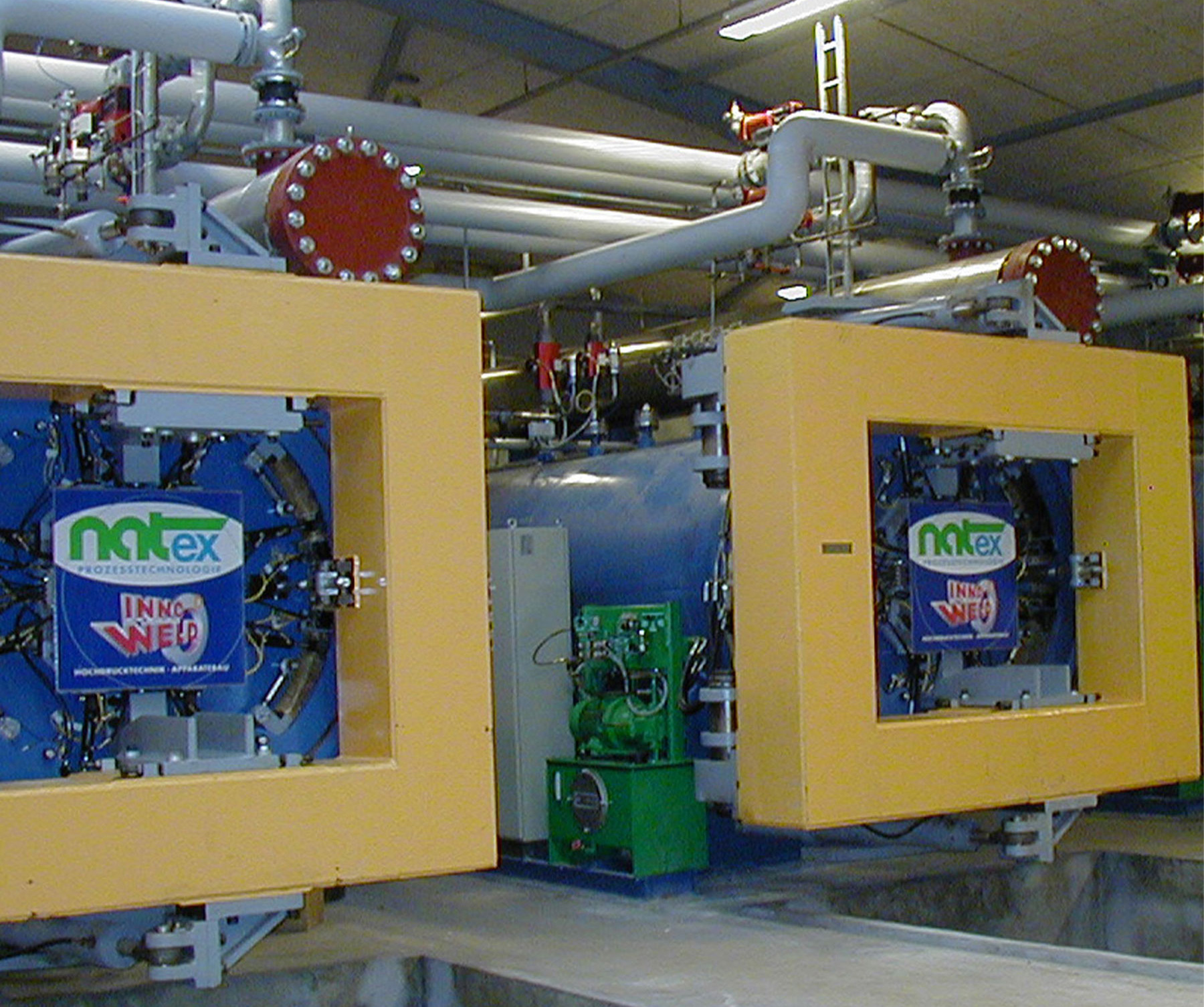

At NATEX Prozesstechnologie GesmbH, we possess extensive experience in supercritical impregnation processes and their scale-up from pilot to industrial scales. Our expertise enables us to develop customized solutions that meet specific client needs while maintaining efficiency and sustainability. With our advanced facilities and knowledgeable team, we are at the forefront of implementing supercritical CO₂ technologies across various applications. This includes the production of samples for clients which are interested to explore the potential of this technology.