Powder Generation with Supercritical CO₂

Overview

Spray processes based on supercritical CO2 allow the generation of powders and composites with characteristics that can hardly be obtained by classical methods. For example the Particles from Gas Saturated Solutions (PGSS) and Concentrated Powder Form (CPF) processes offer tailor-made products and numerous application possibilities, particularly for industries such as food, pharmaceuticals, cosmetics, paints and varnishes.

Principles

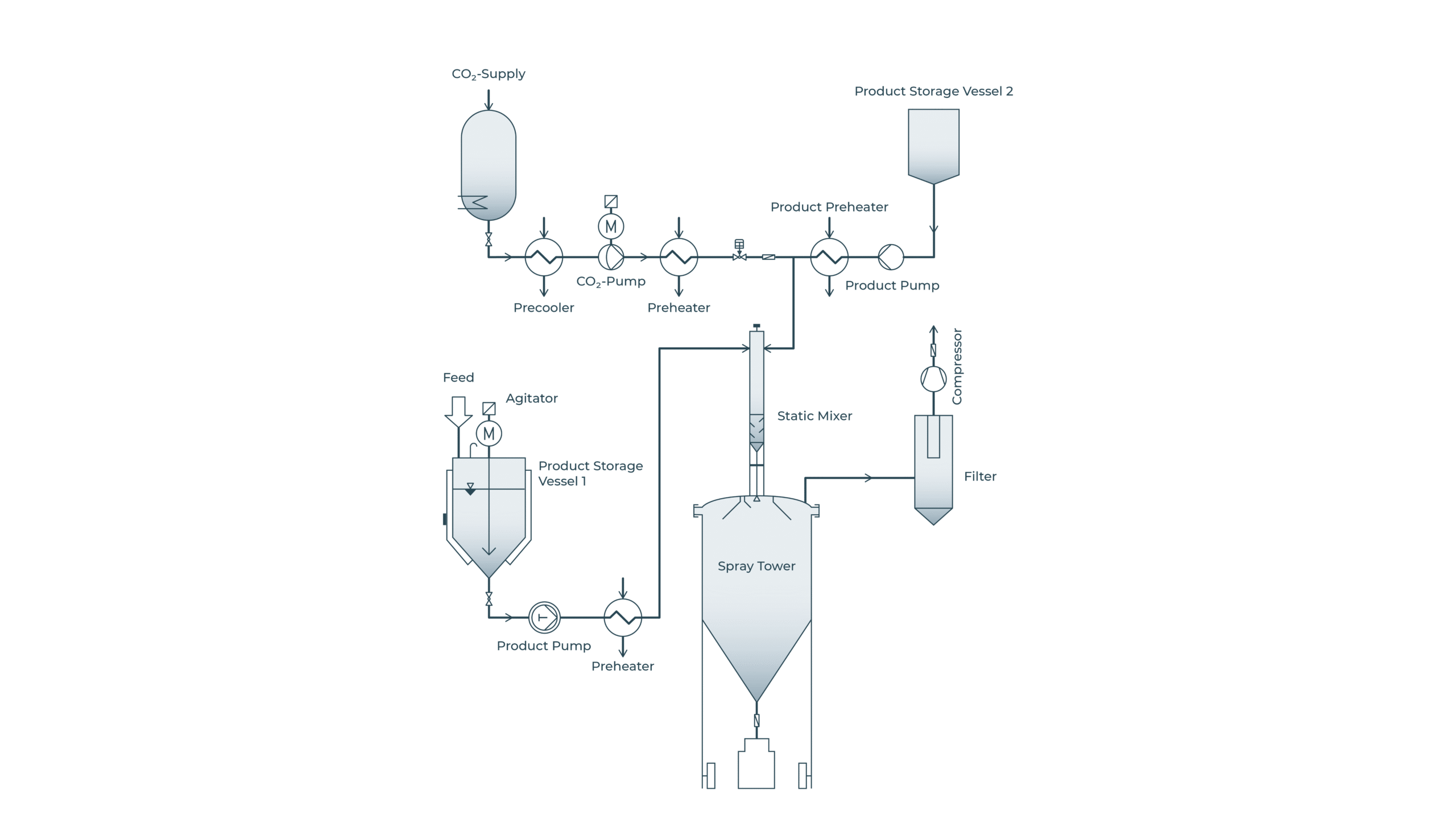

The PGSS process involves melting a substance and mixing it with CO2 in a high-pressure static mixer, where the dense gas dissolves partly in the melt, reducing viscosity. The mixture is then expanded via a nozzle into a spray tower. Upon expansion, the solubility is immediately reduced, causing the liquid to disintegrate into tiny droplets. Due to the Joule-Thomson effect, the gas cools down rapidly, solidifying the droplets almost immediately. Most particles can be collected on the bottom of the spray tower, whereas finer particles are removed from the gas by means of a cyclone.

The CPF process generates powders from liquids that are not solidified themselves during spraying. Liquid and gas are pressurized, mixed together, and expanded into a spray tower. A powderous carrier is also dosed into the produced fine droplet spray, forming a powder with a liquid content of up to 90 wt.-%.

Particle Morphologies

The morphologies of the particles depend on processing parameters such as pressure, temperature, mass flow, and gas-to-product ratio. Various forms can be generated, including:

Composite Production

Apart from powders from pure substances, composites can also be produced. In this case, two vessels are used for the raw materials. The first vessel contains the shell material (e.g., a polymer, fat, or wax) which is melted. The second vessel contains the liquid substance. Both materials are pressurized and mixed with supercritical CO₂ in a static mixer, forming micro droplets of the liquid substance in the molten encapsulating material. The emulsion is expanded through a nozzle into a spraying tower, forming fine droplets. Due to the Joule-Thomson effect, the gas cools down rapidly and withdraws heat from the sprayed substances, causing the shell material to solidify. Depending on processing parameters, open or closed composites are formed together with the liquid.

Other processes

PGSS and CPF are not the only processes available but there are also other processes for powder generation which are based on supercritical CO2 like:

RESS, where the product is dissolved in CO2 before it is depressurized into a vessel

GAS/SAS (SEDS), where the product is dissolved in a solvent before it precipitates out by using CO2 as a anti solvent.

There are even further processes which utilize CO2 for the generation of powders which might be adjusted to the individual task at hand.

Process Advantages

The PGSS and CPF processes offer several advantages:

Applications

Powder generation with supercritical CO₂ is used to produce:

Examples of Powders Produced

Examples of powders produced using PGSS and CPF technology include:

Controlled release properties can be achieved by using appropriate core and shell materials.