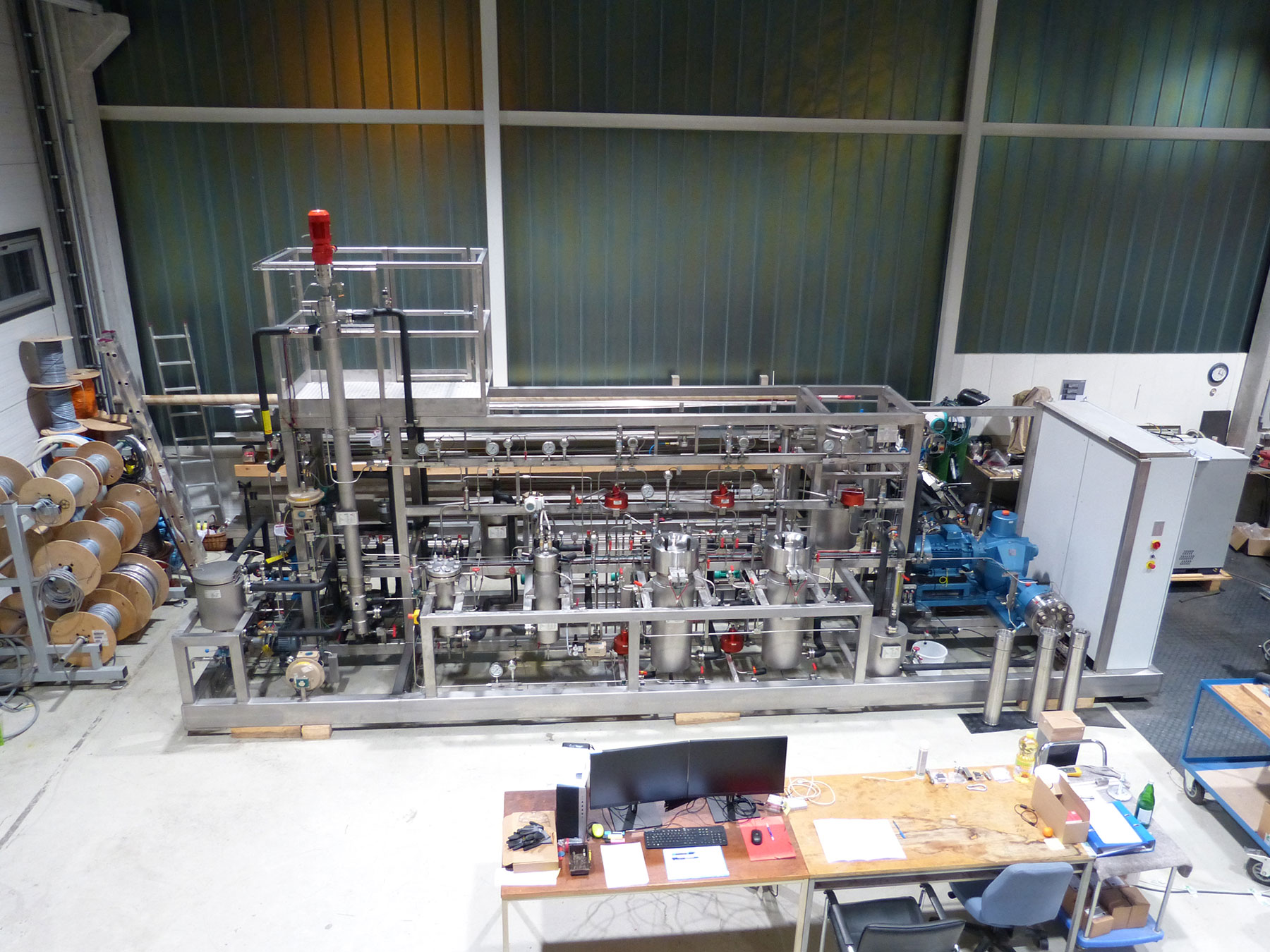

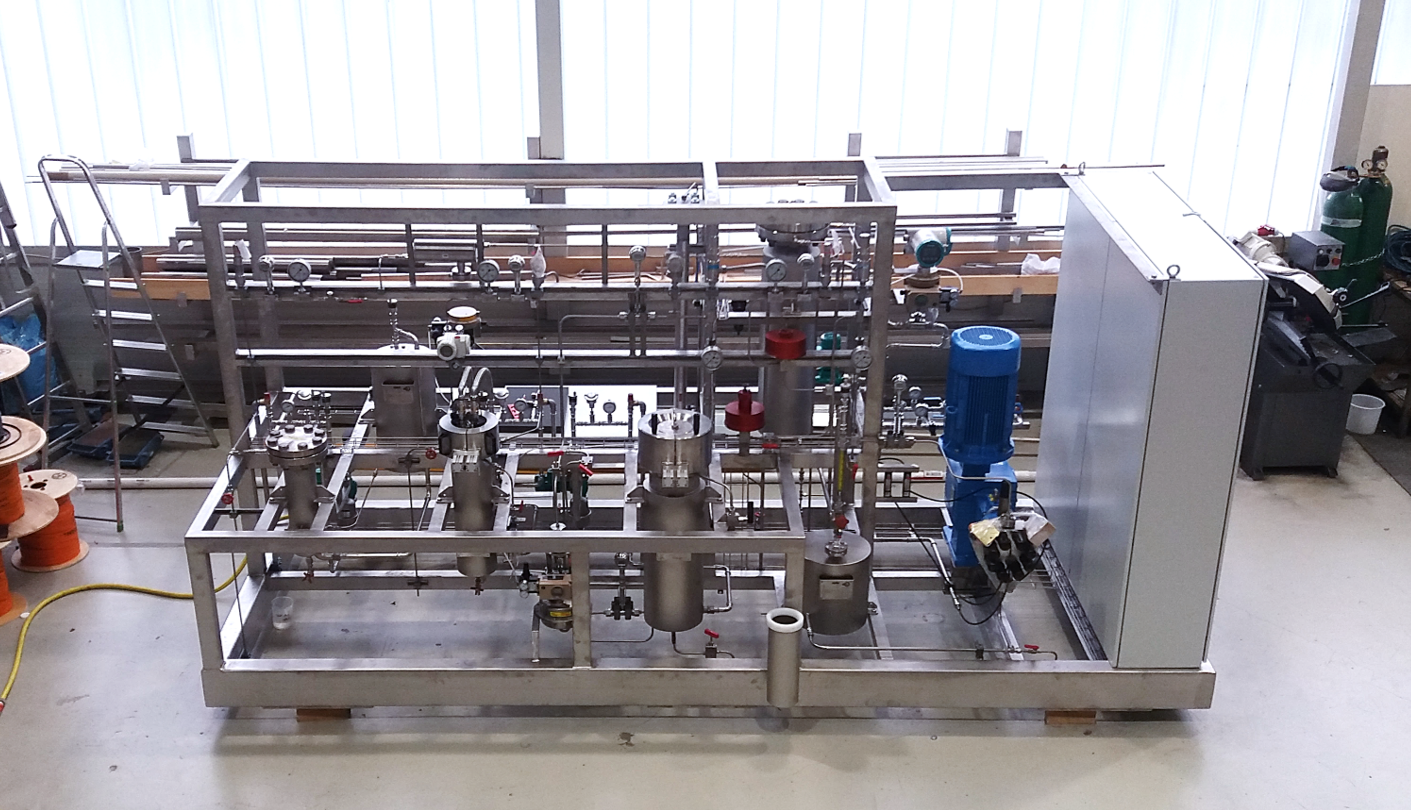

Research and development plants

Natex can provide R&D units or pilot plants based on existing standards or according to the individual requirements of each client. Those units are generally designed to meet all relevant requirements for developing a full-scale CO2 based process later on. This means that the supercritical CO2 extraction unit can work with all types of material without any limitations that some equipment might possess. This is especially related to the process conditions, where the plants are designed for at least 550 bar design pressure and for working with materials that might form solid extracts. The separators are able to collect these solid extracts without clogging and enabling to gain them in a way that does not need the use of high temperatures that may destroy or modify them. We believe that a proper equipment is essential for studying the possibilities of CO2 as a process fluid and therefore make sure that the quality is the same as on an industrial plant. This is the only way to collect data that will allow a quick and successful transformation to an industrial plant.

The features of our R&D or pilot plants include:

- Handling of solid extracts without blocking

- Closed CO2 cycle with recovery

- Membrane pump for hygienic requirements

- Quick opening closures on Extractor and first Separator

- Industrial valves (no freezing)

- Industrial Instrumentation

- Advanced process control system as used on industrial plants and GMP ready

- Multi-stage alarm management (product & human safety)

- Modern visualization incl. online monitoring of plant

- Individual user authorizations and tracking of all operations

- Full reporting of all collectable data for each experiment

- Low inside surface roughness in extractors and separators for easy cleaning

- Secured by safety valves

- CE certificate of conformity for complete plant assembly

- Lifetime design & calculation for cyclic load (designed for at least 15.000 extraction cycles) to avoid fatigue on the pressure vessels

The research and development plants are fully tested after their assembly at Natex and will be shipped only after proper training of the operators and fulfillment of the internal tests that confirm that it is functioning according to the specifications. Therefore, the installation at site is fast and it just requires the defined utilities like electricity, pressurized air and CO2 in bottles are available.

We provided a long list of R&D and Pilot units which include the following:

2L / 550 bar research and development plant:

This plant is designed to process 2L of material per batch and to be the most cost-effective solution to start exploring the supercritical CO2 technology at a scale and quality that will allow suitable data collection. It is equipment with a state-of-the-art plant control system that is also used for full scale plants and is superior and safer than conventional PLC systems. This allows good estimations on mass flow rates, times and energy balances for larger equipment. During the design of the plant we were focusing on the requirements of universities and small research organizations that intend to start with CO2 extraction and want to integrate it as fast as possible into their departments. Therefore, this plant is fully standardized with options of integrating a co-solvent pump. It works with a basket and has a separator that allows for the collection of solid material. It is the only model that is produced in stock and could be available very fast to get you started with supercritical CO2 extraction.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information5L & 10L / 1000 bar research and development plant:

A 5L or 10L R&D unit is a premium tool which is designed for full power CO2 research and development or even small production of highly valuable products. It is already equipped with dead space free instruments to allow for very fast and reliable cleaning between the batches of different raw materials and can work up to ~900 bar. Our customers using this tool are typically in the industry for some years already and know exactly why they need the best equipment available for their internal R&D. They often times also own industrial extraction equipment from us and specialize in CO2 technologies. This premium equipment is already designed in different versions but produced only individually on customers’ demand and allows for the integration of specific wishes like several extractors, fractionation column, cold trap or larger separators.

Research plants with thin film extractor

The most sophisticated and flexible plant is a CO2 extraction plant for solid raw materials combined with a thin film extractor or a packed column or even both. This CO2 equipment collectively uses the main CO2 stream with Pump, Separators, Evaporators and Working Tank but can either process liquid raw materials in the column or solids from the extractor(s).

Individual R&D units

You have your individual process or special requirement? We are happy to adjust the plant to your specific needs and make that your start into CO2 extraction will be successful. Our highly skilled and experienced engineers are happy to develop your plant together with you.

Name of client: R&D and pilot plants

Equipment size: 2 L to 10L / 550 bar to 1.000bar

Country of installation: Italy, Germany, New Zealand, Korea, India, Spain, Poland, China, Taiwan…

Product processed: all types of liquid and solid raw materials