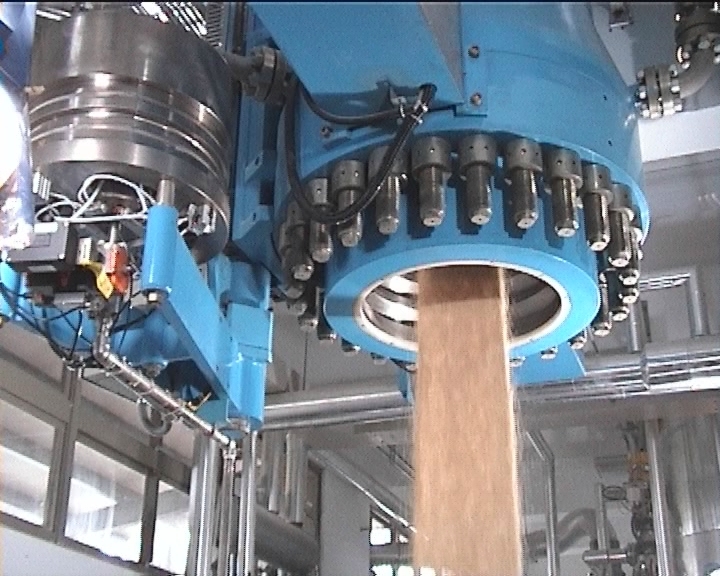

Rice treatment plant

NATEX developed an innovative supercritical CO2 extraction process for treating rice, aimed at removing plant-protective agents and contaminants. This process, involved systematic investigations and optimization on both bench and industrial scales to make sure the plant worked as expected. The environmentally friendly extraction plant, operational since 1999, treats over 90 tons of brown and polished rice daily. The process not only reduces harmful residues and undesirable substances, improving taste and shelf life, but also decreases cooking time. This high-pressure extraction technology leverages NATEX’s expertise in the food industry, ensuring substantial quality improvements in rice.

Name of client: Five King

Equipment size: 3x5.800L

Country of installation: Taiwan

Product processed: Rice