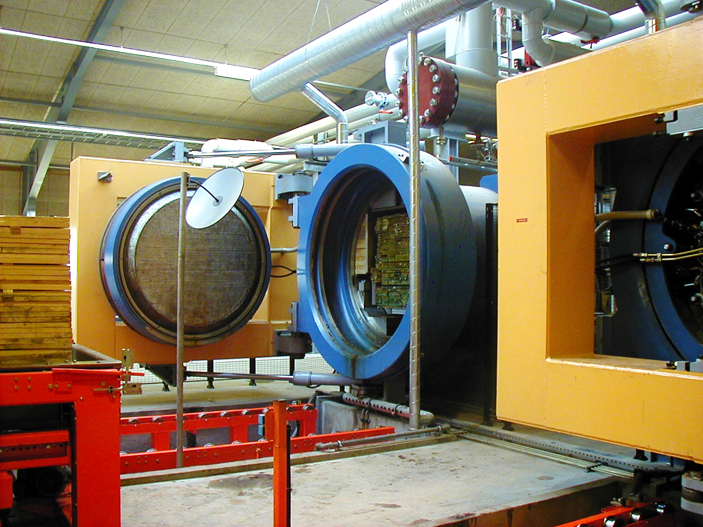

Wood impregnation plant

Timber is a crucial construction material for both indoor and outdoor applications. However, it is often exposed to environmental factors such as rain, wind, sunlight, and biological attacks from insects, rot, and fungi. These factors can cause significant damage, leading to costly renovations.

To prevent such damage, timber surfaces are sealed and treated with biocides. Surface sealing typically involves painting with substances that contain biocides, UV blockers, and materials that prevent moisture penetration. Biocides are usually deposited into the wood using vacuum or pressure methods. Larger structural timber, such as poles and garden fences, is pressure-impregnated with various metal salts, while smaller structural wood, like doors and windows, is impregnated with biocides dissolved in organic solvents using the vacuum method.

The impregnation of wood using supercritical carbon dioxide (CO2) has been developed in Denmark and was industrialized together with Natex because supercritical CO2 can penetrate the wood completely, carrying dissolved biocides with it.

Supertrae A/S in Hampden, Denmark, began industrial-scale wood impregnation using supercritical CO2 in 2002. This investment spurred significant development efforts in the wood industry.

The most important active ingredients for wood impregnation are Tebuconazole Propiconazole and IPBC, which have been successfully used for vacuum impregnation since the early 1990s. Despite limited initial knowledge,

The actual impregnation process involves placing the wood in an impregnation vessel, adding the required amount of active ingredients to a mixing vessel, and circulating CO2 with the active ingredients through the impregnation vessel to ensure even distribution. The vessel is then depressurized, and excess active ingredients are separated for recycling.

Name of client: Superwood

Equipment size: 3x17m³

Country of installation: Denmark

Product processed: Wood boards