Fractionation of liquid mixtures, pastes or dispersions with supercritical carbon dioxide

Fractionation is the process of separating a mixture into its individual components based on differences in their physical or chemical properties. Supercritical CO2 serves as an excellent solvent for this purpose due to its unique properties :

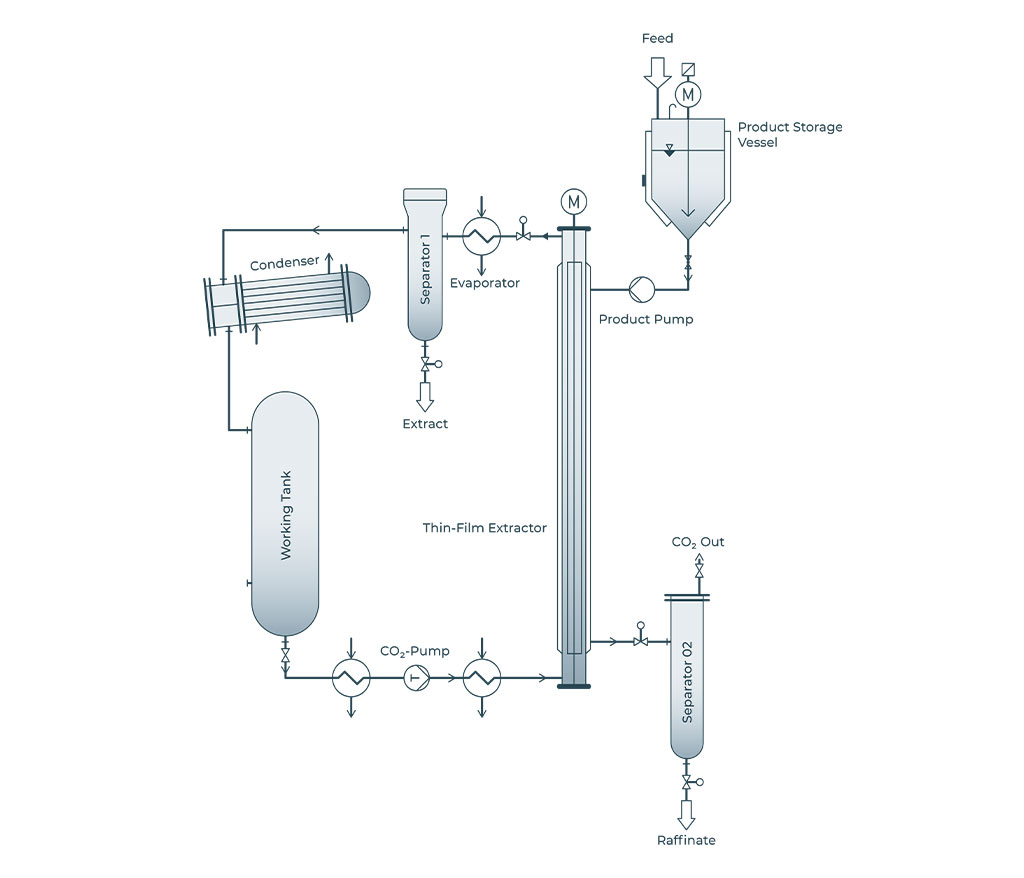

CO2 can be used in the fractionation of liquid mixtures in both packed columns and thin film devices. The later is an innovative approach that offers efficient and environmentally friendly solutions for separating complex mixtures, especially those that are viscous or granular yet still flowable.

Packed Column Fractionation

A packed column is a vertical cylindrical vessel filled with packing materials such as rings, saddles, or structured packings. These materials provide a large surface area for interaction between the liquid mixture and the supercritical CO₂.

How the Column Works in Relation to Mass Transfer

Substances Suitable for Fractionation Using Packed Columns

Thin Film Device Fractionation

Thin film devices, such as wiped film evaporators, are designed for mixtures that are too viscous or granular for traditional packed columns.

Mixtures That Can Be Processed

Our Expertise at NATEX Prozesstechnologie GesmbH

At NATEX Prozesstechnologie GesmbH, we possess extensive knowledge and experience in developing high-pressure processes utilizing supercritical CO₂. Our capabilities include:

At NATEX Prozesstechnologie GesmbH, we are committed to advancing this field and providing our clients with innovative solutions backed by practical experience and state-of-the-art facilities.